As sustainable fashion and eco-friendly textiles become more essential in today’s global market, bamboo fabrics are gaining significant attention. With their renewable origins, softness, and breathability, bamboo-based materials are a preferred choice for both consumers and ethical fashion brands. However, not all bamboo fabrics are created equal. Two widely used variants—bamboo viscose and bamboo lyocell—differ greatly in terms of sustainability, manufacturing processes, and performance. In this blog, we delve into the key differences between bamboo viscose and bamboo lyocell to help you make informed and responsible choices.

What Is Bamboo Viscose?

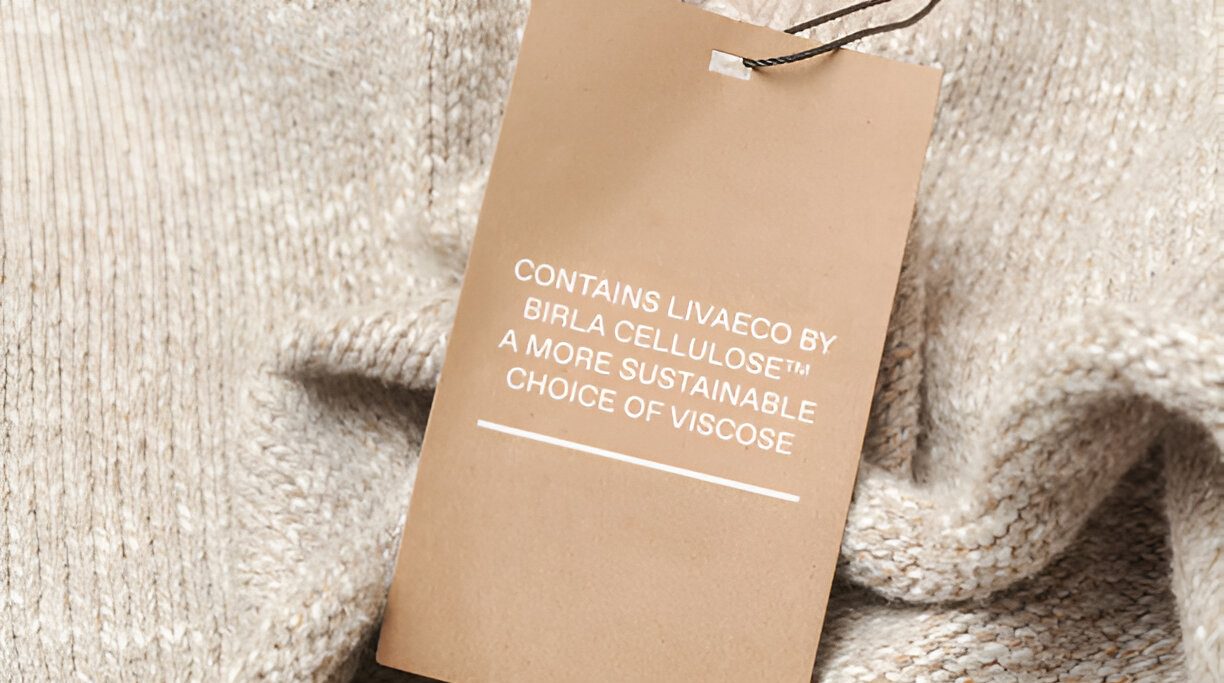

Bamboo viscose, also known as bamboo rayon, is a regenerated cellulose fiber. It is made by chemically converting bamboo pulp into a soft, spinnable fiber. The production process typically involves the use of harmful chemicals like sodium hydroxide and carbon disulfide in an open-loop system, where these substances are not fully recovered or reused.

How Bamboo Viscose Is Made:

- Bamboo is harvested and crushed into pulp.

- The pulp is treated with strong chemicals.

- The resulting viscous solution is extruded through spinnerets to form fibers.

- These fibers are spun into yarn and woven into fabric.

Pros of Bamboo Viscose:

- Soft and luxurious feel

- Breathable and lightweight

- Affordable and widely available

Cons of Bamboo Viscose:

- Uses toxic chemicals

- Open-loop system contributes to environmental pollution

- Health risks for factory workers

- Often lacks transparency in sourcing and production

What Is Bamboo Lyocell?

Bamboo lyocell is a newer, more sustainable bamboo fabric. It is manufactured using an environmentally-friendly closed-loop process, which minimizes waste and recycles water and solvents. The primary solvent used is N-Methylmorpholine N-oxide (NMMO), a non-toxic and biodegradable alternative to conventional chemicals.

How Bamboo Lyocell Is Made:

- Bamboo is harvested and turned into pulp.

- The pulp is dissolved in NMMO in a closed-loop system.

- Over 99% of the solvent is recovered and reused.

- The fiber is then spun into yarn and woven into fabric.

Advantages of Bamboo Lyocell:

- Closed-loop process with minimal waste

- Non-toxic solvents

- Soft, smooth, and durable fabric

- Hypoallergenic and antibacterial properties

- High moisture-wicking and breathability

Limitations of Bamboo Lyocell:

- Higher cost due to advanced technology

- Limited availability compared to bamboo viscose

Bamboo Viscose vs Bamboo Lyocell: Environmental Impact

While both fabrics are derived from the bamboo plant, their environmental footprints differ drastically.

| Aspect | Bamboo Viscose | Bamboo Lyocell |

|---|---|---|

| Chemical Usage | Harsh chemicals (NaOH, CS2) | Non-toxic solvent (NMMO) |

| Process Type | Open-loop (pollution risk) | Closed-loop (minimal waste) |

| Solvent Recovery | Low | 99%+ |

| Worker Safety | Potential health hazards | Safer working environment |

| Water & Energy Usage | High | Low |

Verdict: Bamboo lyocell is the superior eco-friendly fabric.

Fabric Performance Comparison

Both bamboo viscose and lyocell offer impressive fabric qualities, but lyocell has a performance edge.

| Feature | Bamboo Viscose | Bamboo Lyocell |

|---|---|---|

| Softness | High | Higher |

| Breathability | Excellent | Excellent |

| Moisture-Wicking | Good | Superior |

| Durability | Moderate | High |

| Skin Sensitivity | Suitable | Ideal for sensitive skin |

Cost vs. Conscience: Which Should You Choose?

Bamboo viscose may be the more budget-friendly choice, but its environmental toll makes it a less ethical option. On the other hand, bamboo lyocell offers superior sustainability and fabric performance but at a higher cost. For conscious consumers and ethical clothing brands, the long-term benefits of lyocell outweigh the price difference.

Choose Smarter, Live Greener

As eco-conscious living becomes the norm, making smarter fabric choices is crucial. Bamboo lyocell represents a cleaner, safer, and more sustainable future for textiles. Its minimal impact on the environment and superior fabric qualities make it a top choice for those who care about both style and sustainability. While bamboo viscose still dominates the mass market due to its affordability, the future clearly leans toward cleaner technologies like bamboo lyocell.